Classification

Email:denya@chun-wang.com

Address:Chunwang Industrial Park, Tongle Sixth Industrial Area, Longgang District , Shenzhen, China.

Oxygen Absorber(Eye-Marked Type)

Spec:20CC/30CC/50CC/100CC/200CC/250CC/300CC

Packing qty: 10,000pcs/8,000pcs/6,000pcs/4,000pcs/3,000pcs/2,200pcs/2,000pcs/1,800pcs

Type: high efficient general type

Printing: Chines&English with Eye Mark

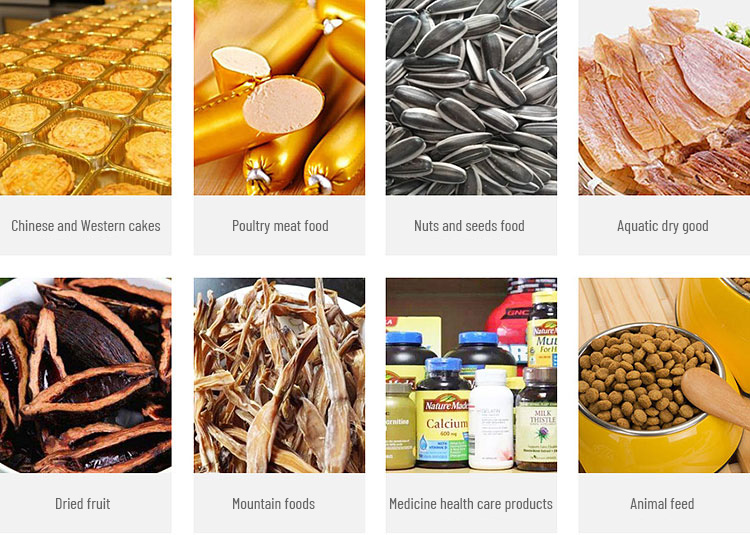

Application

Widely used in Chinese and Western cakes, poultry meat food, nuts and seeds food, aquatic dry good, other mountain foods, medicine health care products, animal feed, and other non-food products.

Why Use Oxygen Absorber?

Because food packaging bags have a certain rate of oxygen,without Oxygen Absorber, oxygen will slowly enter the packaging, thereby providing conditions for the growth of mold and aerobic bacteria, resulting in food mold, oil acid, brown oxide and vitamin loss and etc.

Tips:

(1).Mold belongs to the microbiome, although it belongs to the lowest class of organisms, but it is like other organisms, it has a close relationship surrounding environment in its life activities. Mold growth mainly depends on nutrients, oxygen, water, temperature four living conditions. Oxygen Absorber can remove oxygen from food packaging containers, thus destroy the growth and reproduction conditions of mold, thus solving the problem of food mold.

(2).Food grease acid sepsis refers to oily food, in the storage process by bacteria microorganisms, enzymes, oxygen, light, temperature of the joint action, and the occurrence of color changes, odor changes and other sensory changes (such as hala flavor, etc.). Using Oxygen Absorber remove oxygen from food packaging containers can destroy the essential conditions for oil acid failure.

(3)Food oxide browning is the result of the formation of phenolic substances and their polymers by phenolic enzymes in food, which can affect the food's perception, taste and, over time, will lead to food corruption. Enzymatic browning must have three conditions: proper phenolic substrates, phenolic oxidase and oxygen, which are indispensable. Therefore, the use of Oxygen Absorber to remove oxygen in food packaging containers, can destroy the necessary conditions for enzymatic browning.

How To Use?

Three steps to use (1) calculate the dosage of Oxygen Absorber (2) select suitable food packaging materials (3) put the packets into the food container by manually or automatically, then seal the container well.

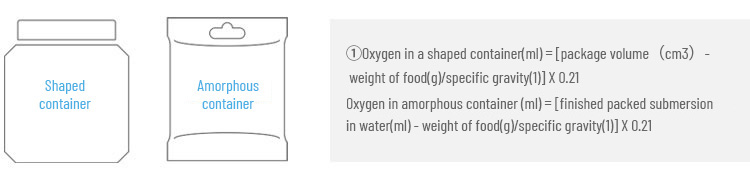

Step one: Calculate the dosage

In order to choose the right size of Oxygen Absorber, it is necessary to calculate two datas (1) the volume of oxygen in the food package (2) the amount of oxygen permeable into the food package during the shelf life. Finally, according to the amount of oxygen absorption of Oxygen Absorber, we can choose the right size.

Notice:

1.The proportion in the formula refers to the relative density of the food (g/cm3). The volume of space occupied by the packaged food can be calculated by the weight (g)/specific gravity of the food.

2.2. Formula 0.21, refers to the proportion of oxygen content in the air is 20.947%, equivalent to about 0.21.

3. Increase in water (ml) refers to the use of drainage method to measure the volume of unsealed packaging.

Notice:

1.The oxygen permeation rate of the package material in the formula (ml/m2.24h.25 degrees C) can obtain the oxygen permeation rate data of the package material from the supplier of the selected package material.

2.The packaging surface area (m2) in the formula can be calculated by expanding the packaging measurement to obtain data.According to the above formula calculated (1) the volume of oxygen in the food packaging (2) the sum of the oxygen volume permeated into the food packaging during the shelf life, that is the total amount of oxygen to be absorbed, and then according to this data to select the right size of Oxygen Absorber (please feel free to contact our customer service regarding the dosage, the model numbers will not be the same from different manufacturers).

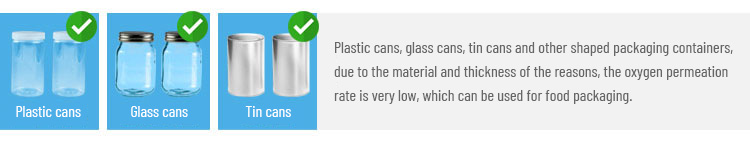

Step two: Choose a suitable food packaging container/material

Shaped packaging: plastic cans, glass cans, tin cans, etc

Non-shaped packaging: non-stereotyped food packaging should choose oxygen permeability of 20ml/m24h.25c or less composite packaging materials, such as KOP/CPP, NY/PE, KNY/PE, KPET/PE, PET/AL/PE, etc., do not use high permeability of packaging materials, such as: OPP/CPP, PP or PE membrane bags.

Step three: put the packets into the food container by manually or automatically, then seal the container well.

Manually: No need to invest automatic dispenser, suitable for purely artificial packaging of food manufacturers or inconvenient machine food delivery.

Automatically:Suitable for fully automatic or semi-automatic food production enterprises, saving labor costs, more hygienic. Stable cooperation with customers, Chunwang can provide automatic dispenser, can inquire about customer service staff.

Notice:

1) Put the food (items) together with oxygen absorber in a container with low oxygen permeability (20ml/㎡.25℃.24h/atm), like KOP/PE,KPET/PE bag or Plastic cans, glass cans and tin cans.

2)The sealing container, the packing material need to be vacuum seal, avoiding the air to enter.

3)After bag opened, better use up within 1-2 hrs and seal the container. The left packets should be reseal in vacuum condition.

4)DO NOT MICROWAVE,DO NOT EAT.Not available for foods with high Aw.(>0.85).

5)The suitable temperature of operation is generally 5-40 ℃; below 5 ℃, oxygen absorbing effect is decreased.

6)During the reaction, packet will release a small amount of heat, this is normal and safe.

Technical principles

Oxygen Absorber is not a food additive, through the principle of iron powder oxidation, absorption of oxygen in the packaging container, in 0.5-2 working days to quickly drop the concentration of oxygen in food packaging to less than 0.01%. In order to ensure that the goods are not oxidized and bad. Its reaction is stable, no harmful gas generation, no side effects.

Chunwang's formula, the main ingredients are reduced iron powder, activated carbon, diatom soil, zircon, sodium chloride, water. Before oxygen absorption is black with gray particle mixture, after oxygen absorption it becomes brown. The oxygen absorption is greater than the national standard "3 times standard oxygen absorption."

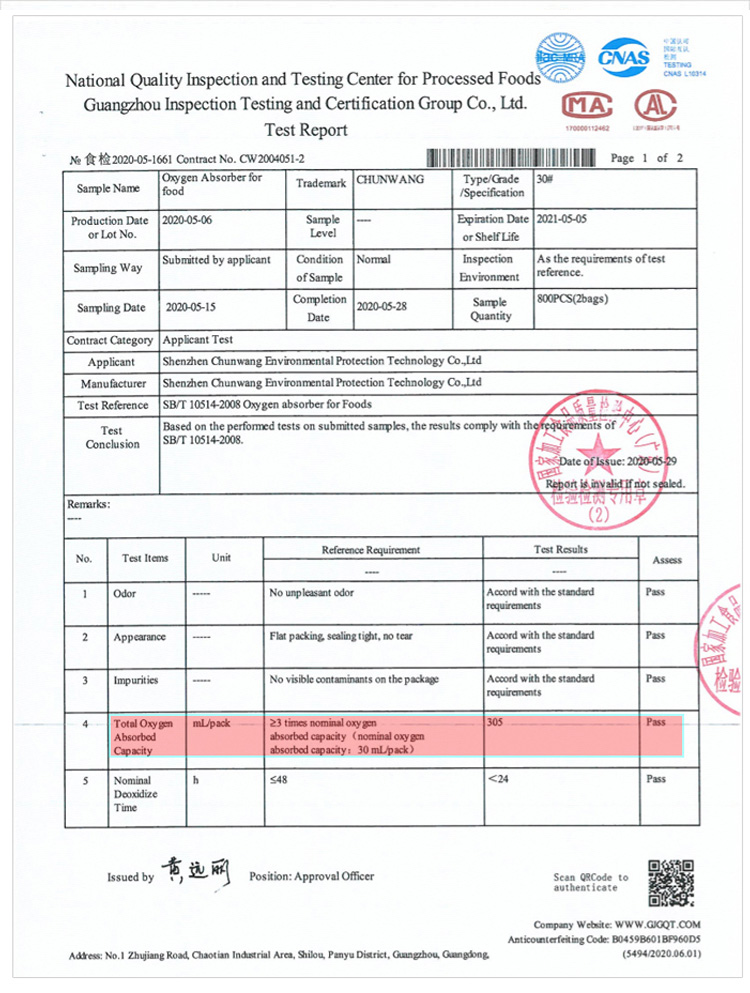

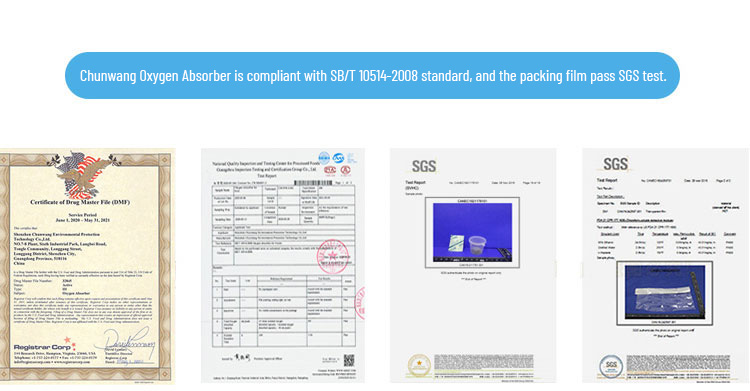

Test Reports

Third-party professional testing institutions testing, oxygen absorption can reach 305ml (to 30 type, for example, the standard oxygen absorption is 30ml/pack, the national standard ≥3 times the standard is called oxygen absorption, that is, ≥90ml/pack is qualified; Chunwang Oxygen Absorber oxygen absorption is 305ml/pack, far higher than the national standard). By the third-party professional testing institutions testing, oxygen absorption can reach 305ml (to 30 type, for example, the standard oxygen absorption is 30ml/pack, the national standard ≥3 times the standard said oxygen absorption, that is, ≥90ml/pack is qualified; Chunwang Oxygen Absorber oxygen absorption is 305ml/pack, far higher than the national standard).

Production and Packing

High-speed machine production, vacuum sealed bag and thickened corrugated export cartons,safe for transportation and storage.

Chunwang VR: http://desiccant.chun-wang.com/chunwang_vr.html

| * Name: | |

| *E-mail: | |

| * Inquiry: | |

| Please fill in the product name and quantity you want to inquiry. | |

| VerCode: |

|

- Oxygen Absorber (With Indicator)

- Product category: Oxygen Absorber (With Indicator)

Raw materials:Iron powder、Activated carbon、Diatomaceous earth、Vermiculite、Sodium chloride、Water.

Spec:30CC/50C100CC

Packing qty: 8,000pcs/6,000pcs/4,000pcs per carton

Type: With Indicating line

Printing: Chines&English

- External Control Antistaling agent

- Spec:50#

Other Spec:50#、100#、150#、200#、250#

Size: 40x 35 mm

Print:Chinese、English、Japanese

Raw materials:Edible starch、Silicon dioxide、 Edible alcohol

- Organic Deoxidizer

- Product category: Oxygen Absorber (Organic Type)

Raw materials:vitamins、carbonated alkali 、water retention agent 、aqueous alkali

Spec:30CC/50CC

Packing qty: 4,000pcs/3,000pcs per carton

Type: Organic

Printing: Chines&English

-中文版

-中文版 -ENGLISH

-ENGLISH